|

||

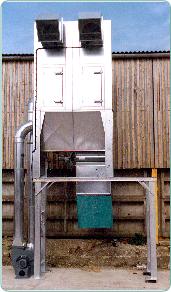

Shaker Filters/Collectors The Delta Environmental range of shaker filter/collectors are suitable for a wide variety of industrial and agricultural applications where continuous cleaning of the filters is not required and where the contaminated air passes through the extraction fanset. Filtration is achieved by passing contaminated air through static filter sleeves. The type and size of filter sleeve will reflect the specific application and product being filtered. The filter/collector size is rated for individual projects where the type of dust or waste, particle size and quantity of waste is known. Frequently used in joinery and similar wood waste environments, we will always aim to use the lowest possible filtration airspeed to provide the best level of efficiency and to maintain reliable operation. In this application, it is common for the filter/collector to run for 2 – 4 hours between shutdown when the filters are shaken, usually automatically. These filter/collectors are manufactured to each individual customer order, fabricated in high grade pre galvanised steel, and using a modular manufacturing concept with the optimum size of filter sleeves that suits each particular application. This type of construction allows for future expansion of the modules if extraction requirements increase. Contaminated air passes through the fan unit before filtration and our robustly engineered fans are well proven and offer high levels of reliability, even when handling some of the most demanding and abrasive materials. The fan type and style reflects the type of application and can be manufactured in mild or stainless steel, or with a wear resistant alloy specifically designed for highly abrasive applications. |

||

|

|||||||||||||||||||

|

Filter type Double Modulex: The extracted and cleaned air is returned to the factory to prevent heat losses during winter. |

Jump to next |

|||||||||||||||||

|

||||

Filter/Collector type Single Modulex: |

||||

|

||||||||

|

Filter/Collector type “Bagging unit”: |

|||||||

Filter type Single Modulex: |

||||||||

|

|

|||||||

Filter/Collector type Single Modulex: |

Single Modulex Filter mounted on Silo: |

|||||||

Delta Environmental Ltd © 2015 |

Home/Contact | Reverse Jet Filters | Shaker Filters/Collectors | Filter Spares & Consumables | Fans–Industrial | Fans & Controllers for Agricultural | Sitemap |

|||